Repair Tips

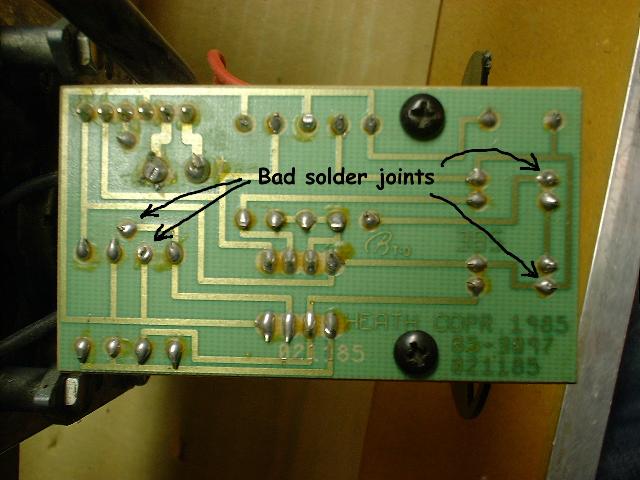

We have worked on a lot of robots over the years and have seen all sorts of odd issues. If you are having trouble with one of your robots make sure you check for some of the obvious issues first. Since many robots were built from kits the quality of soldering and construction can vary wildly. On kit built robots you need to verify that all the correct parts are installed and installed in the correct locations. Some issues to look for are:

Poor soldering. Either solder bridges (short circuit) and cold (open circuit) solder joints. An example that shows what to watch out for that may be an open connection:

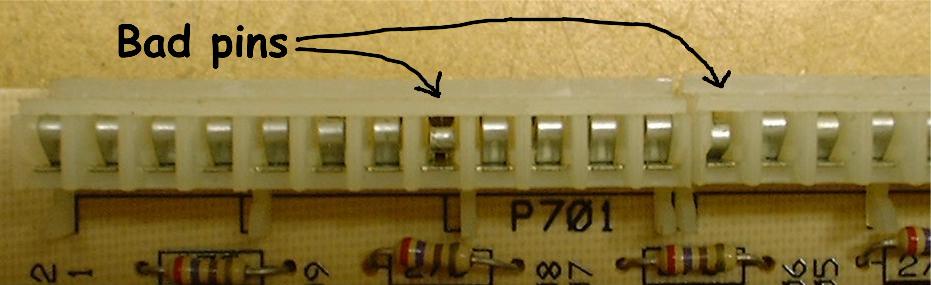

Besides obvious issues with soldering another common issue deals with the connectors. Over time (or abuse) some of the spring contacts can become damaged. The picture below illustrates this:

The issues with bad pins can also occur within connector shells on the end of a wire harness. These can cause intermittent connections that can be time consuming to track down.